3 Reviews

-

very sturdy

it's very sturdy. I like it.

-

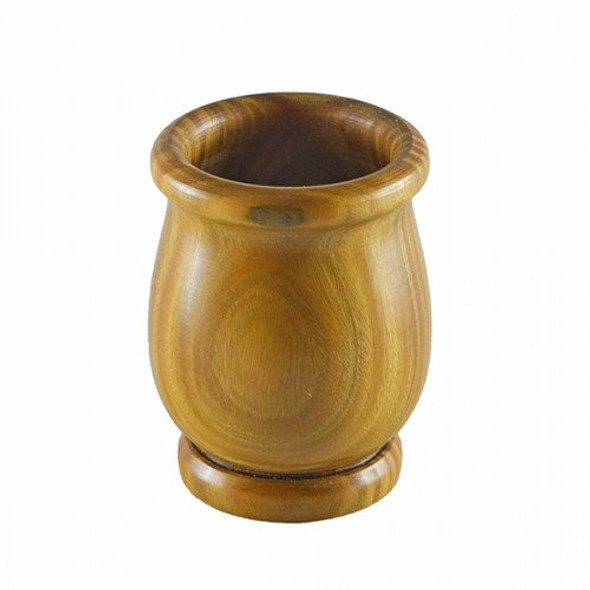

top quality wood mate

The one i recieved has different shape than the picture which shows a fat round mouth with straight sides; the one i recieved has a nice rounded belly and prettier lip on mouth. the metal was very loose and way too big of a diameter for wood, so it was a cinch to remove and there's hardly any adhesive to remove from wood. A great mate which essentially folles contours of metal. The wood on bottom doesn't have a hole in the middle (like some do from producer not removing section of wood where wood was attached to wood lathe.) Nothing was applied to inside. Inside has a great shape and good volume (maybe about 5.5 Ounces).

-

$15 is a steal!

I am an old carpenter and a matero. The wooden part of the mate is really excellent-quality and well-made and feels good in hand once the loose and clunky aluminum "wrap" was removed which was easily cut off. I’m impressed that there is no hole in the bottom which are typically found which are where the wood was screwed onto the lathe wood-turning machine. I reshaped the taper of the base a bit and sanded it and cured it. And this is one great mate. how to cure a wooden mate: FIRST STEP : Cure the outside while leaving the inside raw wood. The traditional way is make and apply a mixture of butter, and beeswax and animal fat, like butter, beef tallow or pig fat, or some neutral vegetable oil. Alternatively, a mixture of beeswax and food grade mineral oil and 100% pure, organic, cold-pressed and unrefined jojoba oil and 190 proof grain alcohol (sold in liquor stores) can be used. The alcohol helps the waxes and oils penetrate into the wood. It’s wise to mix the alcohol in after removing the mixing vessel from the heat source or fire because alcohol is very flammable. Jojoba oil and food-grade mineral oil don’t break down. Setting the mate upside down on some cardboard for the treatment is a good way to prevent the finish getting onto the inside of the mate. Apply a coat ; (can use a small piece of cotton cloth.) Use heat from a heat gun (or any source of heat) to settle and evenly distribute the mixture into the wood. The heat will also help extract wood moisture and replace it with oil. Reapply a couple of coats of the mixture about every 5-6 months. The finish looks great and is pretty well perfectly waterproof. DO NOT USE standard “boiled linseed oil”: in it are industrial petroleum-based solvents and metallic dryers ; (the most commonly used heavy metal dryer in “boiled linseed oil” is cobalt that is considered toxic.) If you would like to use boiled linseed oil, use 100% pure polymerized linseed oil. Although it’s “Not for food or hygiene applications.” since it’s not going on the inside it should be just fine. DO NOT USE a finish generically referred to as “Danish Oil” is produced by large paint manufacturers and contains some linseed oil but the majority of the components may be carcinogenic, petroleum-based ingredients such as Naptha, Mineral Spirits, and Dipropylene Glycol Monomethyl Ether. SECOND: Leave the inside untreated / natural wood. After cleaning the inside thoroughly, then fill it up with 190 proof grain alcohol (or 90% rubbing alcohol) to soak for a day or two while moving it around and rubbing the insides with a brush (a toothbrush with the head bent backwards works well) ; this helps to extract the oils and resin of the wood, to some extent, which produce the woody flavor. Do two rounds of that, it takes at least 3 days to get this right, you'll see how the alcohol darkens and gets some gunky stuff. THIRD: then proceed to cure it with old yerba, (or new if you don't have old yerba mate at hand), by filling it 2/3 full with yerba but instead of water use rum, whiskey or whatever liquor you like the taste of (or if no like taste of any liquor use vodka or even the 190 proof grain alcohol both of which are tasteless), this will prevent nasty stuff to develop and will add some flavor to the mate, leave that for a day or two and you are done.